Roaster Training at The Workshop Saigon

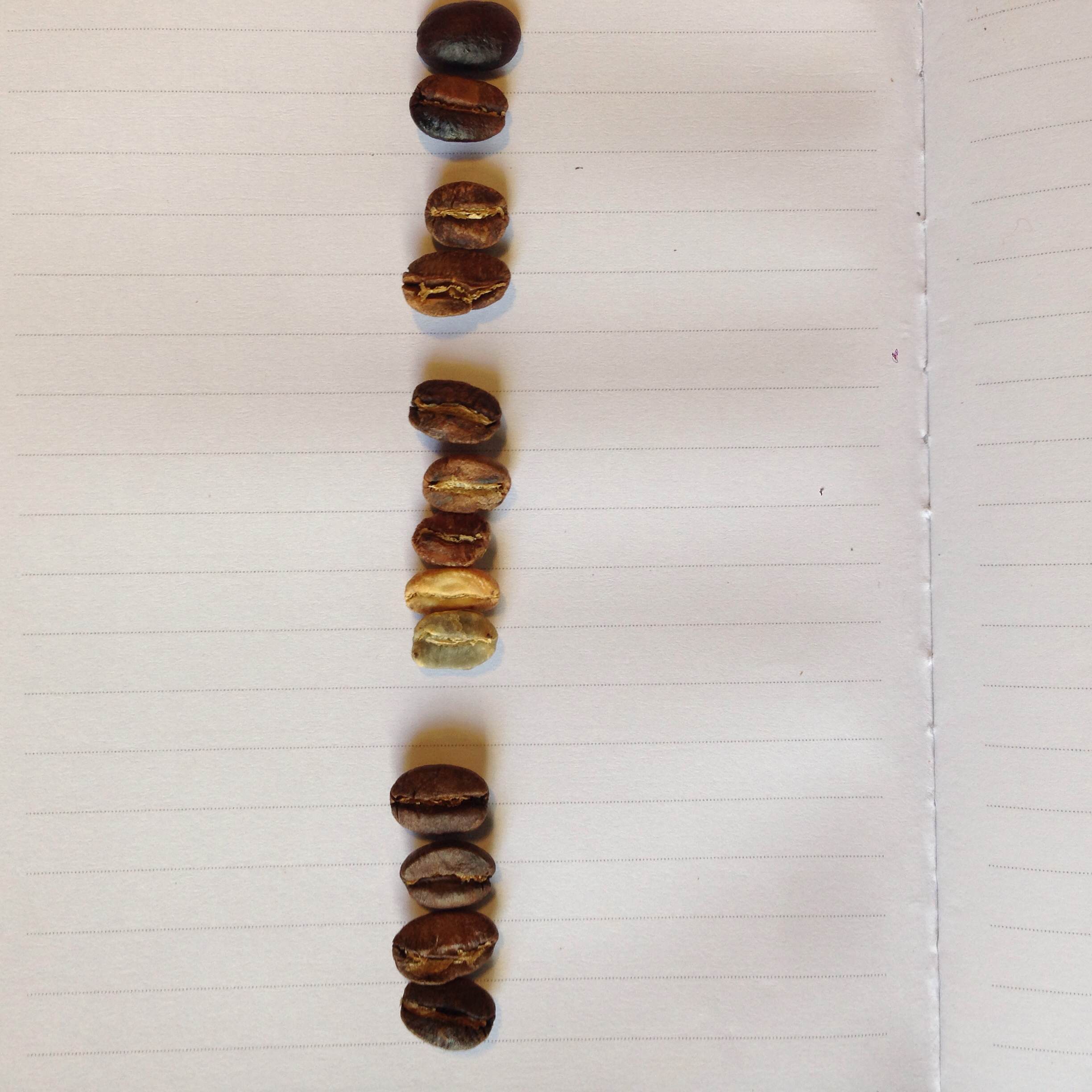

Defect day at The Workshop Saigon roaster training

To start out my training contract with The Workshop, I had to get to know the roaster on my own. I effectively became the production roaster for a couple of weeks, both to orient myself to the machine and to work on some roast profiles for the shop. Luckily, the roaster was manufactured by my friend Sebastian Heinemann's company Coffee Pro Direct (website only viewable outside of Vietnam). I'd already had some interaction with his machines, so it was fairly easy to get re-acquainted.

This also gave me the opportunity to use roasting software for the first time as a production roaster. In my work as a roaster so far, I've relied on a decidedly analog approach, using nothing more than my senses, a roast log, and my intuition. We decided to download the open-source (free!) Typica software and install the probe ourselves (with a little help from Sebastian). I was a little scared at first because it was something new, but also eager to learn how the data I received could improve my own roasting and that of my clients'. It's very basic software but extremely useful.

For the entirety of the training we focused on one single coffee, a Typica blend from Dalat, so as to eliminate variables and focus on the relationship between the roaster and the coffee. I started training The Workshop co-owner Dung, La Viet employee Phong and barista Truong on the small 200g Lysander lab roasters, teaching them to exert control during certain points in the roast in a very basic, hands-on way. We spent two full days on the Lysanders learning the basics and theory of roasting, and about roasting defects. Roasting defects day is always fun because we get to roast badly on purpose.

On the third day I acquainted my students with the production roaster, and the systems involved in operating it. My goal was to set up a solid system for roasting that included keeping it clean throughout use, properly warming up the roaster, and the importance of planning that day's batches ahead of time. We made sure to cup at the end of every day to drive home the lessons learned, and to build the practice into their daily system through repetition. This also allowed me to help build the cupping practice for all of the staff, including baristas, who also joined us for cuppings.

Proud Phong & Truong driving the big machine by themselves.

The last week of training has been the most fun, as I've given them team challenges in roasting, where they have to plan out a roast together, then see the batch through without changing their plan in any major way. They've been very good students, and have solved the problems and challenges I've given them quite quickly.

Today was all about profiling. We needed to find the sweet spot for this Dalat Typica, as we had had trouble getting much sweetness out of it without also highlighting an earthy flavor that previous batches seemed to suffer from. I was impressed with how they worked together to solve the problem on paper before they even loaded the batch into the roaster. The resulting coffee had a nice creamy body and flavors of milk chocolate and red apple, with a long sweet finish. The rest of the week will be spent practicing and refining their roasts on this and a few other coffees. My hope for the training is to set up and habituate a positive feedback loop involving a roast plan, batch samples & cupping, and adjustment. As always, my goal as a trainer is to render myself obsolete, and the talented crew at The Workshop isn't making my job very difficult in that respect.